Aerospace maintenance teams live in the space between speed and certainty. You need to inspect quickly enough to protect schedules, but carefully enough to protect safety and reliability. In many shops, the fastest way to lose time is to capture inspection media that is hard to interpret later. Soft edges, glare, and unclear defect boundaries can lead to repeat scoping, delayed sign-off, or conservative decisions that drive unnecessary removals.

That is why modern videoscopes are trending beyond simple viewing. Teams increasingly want tools that help them confirm what they are seeing and document it in a way that others can review with confidence. Vendors such as USA Borescopes support that shift by offering inspection systems built for demanding environments and practical workflows, especially where engine inspection consistency matters most.

The Feature Set That Matters in Engine Inspections

A powerful inspection tool is not defined by a single spec. It is defined by how well its features reduce uncertainty in real inspection scenarios like blades, vanes, liners, and other internal surfaces that are difficult to access and even harder to document consistently.

A strong example is the USA3000J-6 joystick articulation 6mm dual view 3D measuring videoscope, which is built around three core needs for aerospace teams: dual view confirmation, high-resolution imaging, and 3D measurement.

Dual view for confirmation and context

Single-view images can be misleading in turbine environments. Curved surfaces, reflective alloys, and tight chambers create glare and shadows that can distort edges. Dual view helps reduce misinterpretation by letting technicians validate a suspected defect from a second perspective. If a line looks crack-like in one view, the confirming view can help determine whether it is a true indication, a shallow scratch, or a surface deposit. That confirmation step is often what prevents repeat inspections and keeps the decision moving.

Dual view also helps with orientation. When you can see the same area from a second angle, you get better spatial context for where the defect sits relative to features like cooling holes, trailing edges, or transitions between surfaces. That context improves documentation quality and supports clearer internal handoffs.

High-resolution imaging that supports better calls

In aerospace inspection, edges matter. The boundary of a nick, the endpoints of a crack-like indication, and the outline of corrosion all depend on edge clarity. When edges look soft, technicians compensate by taking more images, changing angles repeatedly, and spending extra time trying to confirm what they already suspect.

The USA3000J-6 is listed with 2560×1440 image and video output, which can help support sharper defect boundaries and clearer surface texture in captured media. The practical benefit is fewer borderline images that require explanation later. Better capture quality also helps supervisors and QA reviewers who were not present at the inspection, because the media is easier to interpret without extensive verbal context.

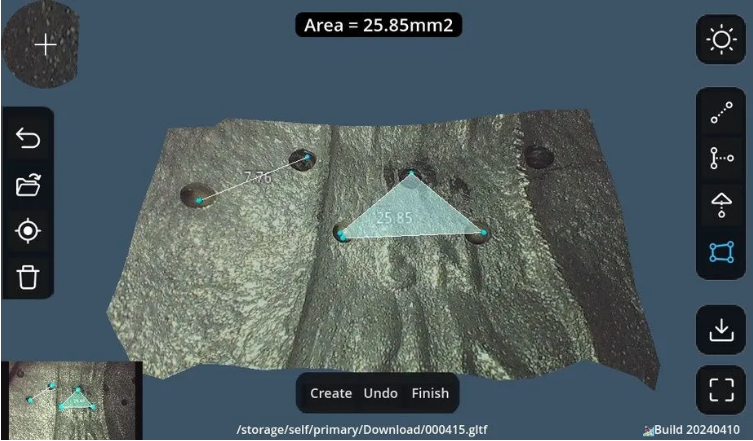

3D measurement that turns visuals into decision inputs

Seeing a defect is not the same as acting on it. Many maintenance decisions come down to size and trend. How long is the indication. How wide is the affected area. Has it grown since the last interval. Measurement capability supports consistency across technicians and shifts by replacing subjective sizing language with repeatable numbers.

The USA3000J-6 lists measurement functions such as point to point, point to line, point to surface, and area measurement, and it also lists an effective measurement range of 10 to 25 mm with a stated measurement error value. The most important takeaway is not the number itself. It is that the tool is designed to produce measurable outputs that can be reviewed and compared over time.

Control and Maneuverability for Confined Inspection Paths

Aerospace teams rarely inspect in comfortable spaces. Engine paths can be narrow and curved, and a small movement can shift the viewpoint enough to lose the target area. That is why control systems and probe handling are not just convenience features. They influence whether a technician can reliably capture the evidence needed for a decision.

Joystick articulation and a stable view

Joystick articulation helps technicians steer into tight geometries and then hold a view steady while capturing media and measurements. The USA3000J-6 is described as having smooth joystick control and a lock system, which supports two practical advantages. First, faster navigation to the target area. Second, better stability once the target is found.

Stability matters for measurement and for documentation. When the image is steady, edges are clearer and the chance of selecting the wrong boundary drops. When the view is stable, it is easier to capture a clean series of images that show both context and detail.

Practical navigation inside engines

Engine inspections often involve repeated turns around geometry where the technician needs to maintain orientation. A controlled articulation system reduces the number of repositioning attempts needed to see behind features or around transitions. That can help reduce scope time, especially in line maintenance contexts where access time is limited.

For maintenance teams, the payoff is not only speed. It is repeatability. When technicians can navigate consistently, they are more likely to capture comparable views across intervals. Comparable views make trending easier and reduce disagreements in reviews.

Measurement Confidence and Repeatability in the Field

Measurement is one of the fastest ways to reduce guesswork, but it is only valuable when it is used with good technique. Aerospace teams benefit most when measurement is treated as a repeatable workflow rather than an occasional feature.

Why 3D measuring beats estimation

Estimating defect size from a single view can be difficult, especially on curved or reflective surfaces. Even experienced technicians can disagree because angle, distance, and lighting all affect perceived size. Dual view and 3D measurement help reduce those variables. Dual view improves confirmation of endpoints, and measurement provides a repeatable value to support the decision.

This matters for decisions like monitor versus remove. If a feature is borderline, measurement helps avoid two common problems. First, overreacting to an issue that is stable and within limits. Second, underreacting to an issue that is growing and should be escalated.

Using measurement the right way

A strong measurement habit is simple:

- Confirm the defect boundary in both views before measuring

- Maintain a reasonable distance and avoid extreme angles when possible

- Capture at least one contextual image and one close-up image

- Record the measurement along with a short location note

When teams follow a consistent routine, measurement results become more dependable, and internal reviews become faster because the evidence is more complete.

Field Readiness for Aerospace Maintenance Work

Aerospace environments are demanding. Tools get moved between bays, carried to aircraft, and handled under time pressure. Field readiness is not just ruggedness. It also includes ergonomics and workflow features that help technicians document efficiently.

Probe size and access planning

The USA3000J-6 is listed as a 6 mm videoscope and currently available in a 3 m working length, which aligns with many common inspection paths in aerospace and industrial applications. Probe diameter and working length influence what you can reach, how easily you can navigate, and whether you can access the target without fighting the path. For teams, selecting a scope often starts with access requirements and only then moves to imaging and measurement features.

On-tool review and documentation habits

The USA3000J-6 listing also notes a 7 inch touchscreen monitor and the ability to add notes or text on the screen, along with reviewing previously captured media. In practice, that can help technicians confirm coverage while still in position. It reduces the risk of leaving the engine and discovering later that the best evidence was not captured.

This type of workflow feature matters because it supports consistent documentation. When the tool makes it easy to review and label media, technicians are more likely to create inspection records that are ready for review the first time.

Team Adoption: Training, Consistency, and Better Handoffs

A tool can be technically strong and still fail to deliver value if it is difficult to adopt. Aerospace maintenance teams benefit most from inspection systems that support standardized routines and make review easier for people who were not present at the borescope.

Faster onboarding and more consistent outputs

Dual view and measurement features can support training by making it easier to validate what a technician is seeing. A newer technician can use the confirming view to reduce misreads and use measurement to support sizing decisions. Over time, that can help tighten consistency across the team.

Consistency becomes especially important when inspections are handed off between shifts or when a finding is escalated. Clear images, a confirming view, and measurement data reduce back-and-forth questions and help supervisors focus on the decision rather than the interpretation.

Better internal reviews and fewer repeat inspections

A common reason for repeat inspection is incomplete evidence. If a reviewer cannot verify the finding from the images, the team may have to re-scope just to confirm boundaries or capture a better angle. Dual view and measurement reduce that risk because they strengthen the record and support quicker sign-off.

For teams managing schedule pressure, this is one of the biggest benefits. Better evidence reduces rework. Less rework protects turnaround times.

A Practical Upgrade for Aerospace Inspection Workflows

Aerospace maintenance teams need inspection tools that shorten decision cycles without sacrificing confidence. The USA3000J-6 stands out as a practical option because its design focuses on confirmation and measurable outputs, not just basic viewing. Dual view supports visual validation. High-resolution capture supports clearer defect boundaries. 3D measurement supports repeatability and trending, which are essential for consistent decisions across technicians and intervals.

For teams comparing inspection systems across applications, a good place to start is the broader USA Borescopes product catalog. When it is time to match a scope to a specific engine path, inspection interval, or documentation requirement, USA Borescopes can help narrow the options and recommend a configuration. To request a quote or discuss fit for your maintenance workflow, readers can contact them.

About The Author

The author is a visual inspection and maintenance reliability specialist with experience supporting aerospace and industrial inspection programs. They focus on practical inspection workflows, documentation quality, and repeatability across teams and shifts. Their work centers on helping technicians turn observations into consistent decisions.